MECHANICAL TREATMENT PLANTS

REŠETILOVS develops and offers

factory made complete mechanical treatment plants

and separate components

for decentralized water management.

RANGE OF PRODUCTS

- mechanical treatment plants

- mechanical screens for coarse solids

- mechanical screens for fine screenings

- grit chambers

- screw conveyors

- stairs, handrails, walkways, fencing

- electrical stands and panels

- electrical channels

- lighting systems

- control panels.

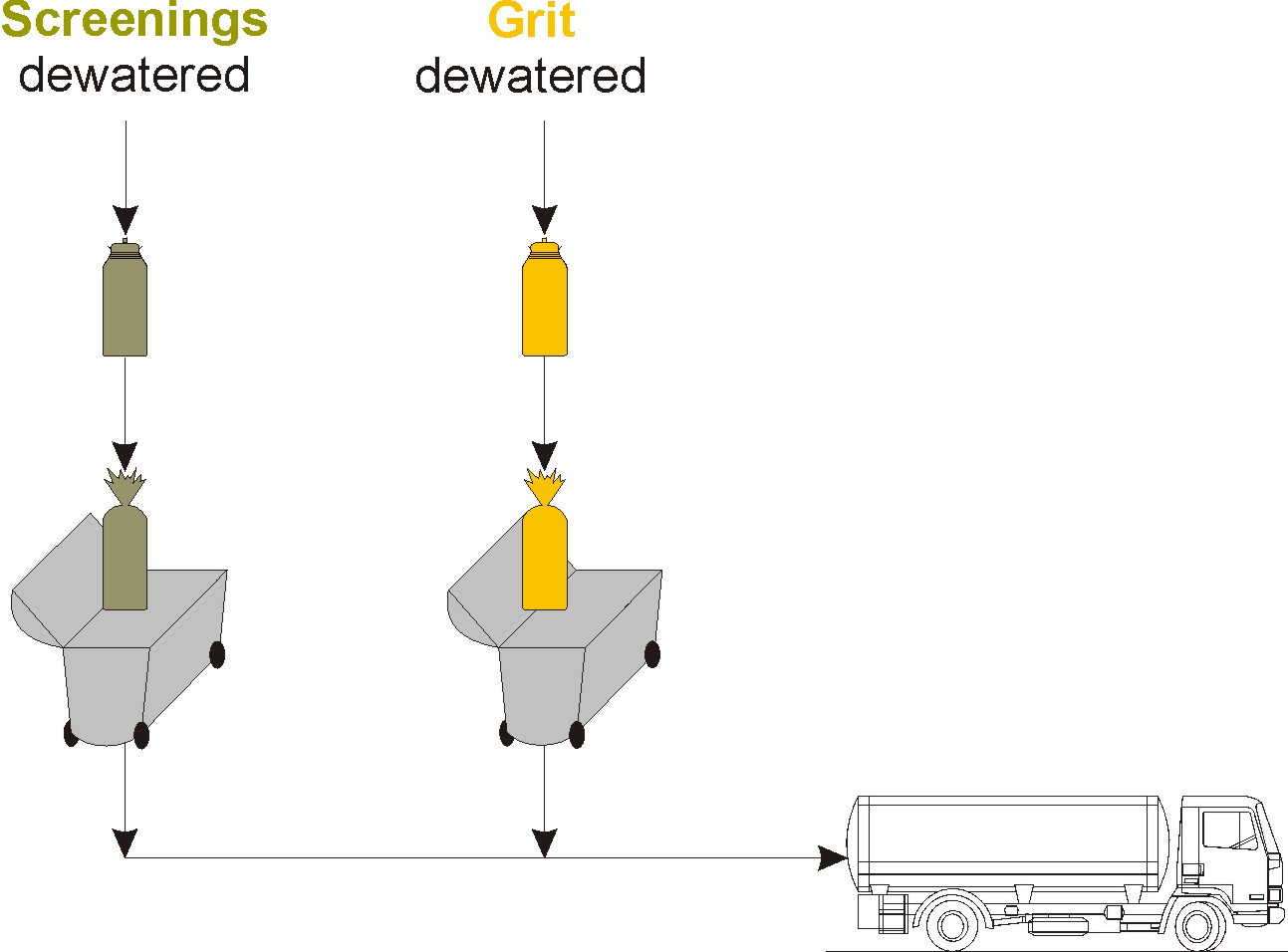

Processed wastes are

ENVIRONMENTALLY FRIENDLY!

APPLICATION:

- coarse screenings removal,

- fine screenings removal and dewatering,

- grit removal and dewatering.

Complete processing and safe handling, storage and transfer arrangement to the following waste utilization from WWTP.

- High treatment efficiency;

- Compact footprint and mobility due to package-modular design;

- Low expenses for foundations of equipment due to small area for it placement;

- Minimal on-site mounting works and no expenses for technological external network due to ready-to-use technological solutions with factory made equipment;

- Low operational expenses due to minimal electrical power consumption and process full mechanization and automation;

- Long-life due to stainless steel use;

- Ecological safety due to complete processing and safe handling, storage and transfer arrangement to the following waste utilization from WWTP.

.png) Fine mechanical treatment plant

Fine mechanical treatment plant

Models range from 15 up to 760 m3/hour

Functionality:

- Fine screenings removal and dewatering. Fine screenings are removed on fine screen and dewatered on hydraulic press.

- Grit removal and dewatering. Grit is removed in grit chamber and dewatered on screw conveyors.

Design:

- frame module system;

- containerized system.

Fine mechanical treatment plant

Fine mechanical treatment plant

Models range from 10 up to 84 m3/hour

Functionality:

- Fine screenings removal. Fine screenings are removed on fine screen.

- Grit removal and dewatering. Grit is removed in grit chamber and dewatered on gravity type unit.

Design:

- frame module system;

- containerized system.

Fine screening unit

Fine screening unit

Models range from 31 up to 56 m3/hour

Functionality:

- Fine screenings removal. Fine screenings are removed on screen.

Design:

- open type trough.

Screen for coarse screenings removal

Models range from 18 up to 36 m3/hour

Functionality:

- Coarse screenings removal on manually cleaned screen.

Installation:

- placed in ferro-concrete or fiber-glass plastic reservoir on WWTP site.

.png) Basket for coarse solids handling, storage and transfer

Basket for coarse solids handling, storage and transfer

Models range from 40 up to 400 l

Functionality:

- Coarse solids handling, storage and transfer in basket, which is emptied manually or by lifting device in process of filling.

Installation:

- placed in ferro-concrete or fiber-glass plastic reservoir on WWTP site.

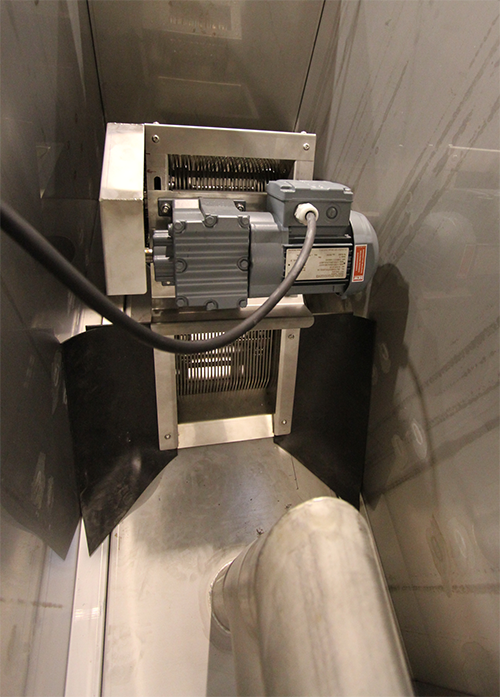

Fine screen

Models range from 31 up to 56 m3/hour

Functionality:

- Fine screenings removal. Rakes are installed inside of screen. Rakes take up screenings from fine screen bottom part and throw them into refuse chute.

Installation:

- plaсed in open type trough or other place.

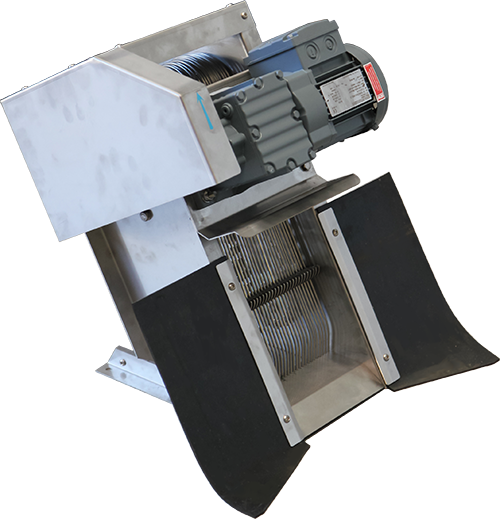

Models range from 10 up to 760 m3/hour

Functionality:

- Fine screenings removal. Screenings are gradually removed by moving plates package and throw them into refuse chute.

Installation:

- placed in special type trough.

Hydraulic press

Functionality:

- Screenings dewatering. Screenings are dewatered on hydraulic ram press due to counter pressure generated in discharge pipe.

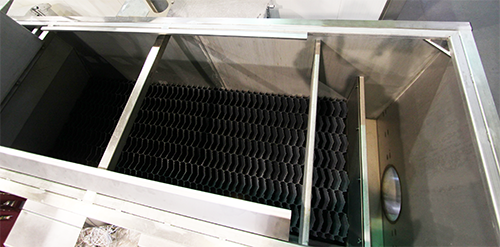

Grit removal unit

Functionality:

- Grit removal. Grit settles on inclined plates, thickens and slips into hopper bottom of grit removal unit.

Grit dewatering unit

Functionality:

- Grit dewatering. Grit is dewatered by gravity with special filtration bag.

Screw conveyor

Functionality:

- Grit dewatering. Grit is dewatered on screw conveyor in pipe with screw bar.

Power supply and control panels

Functionality:

- Power supply and control. Mechanical treatment components can be equipped with power supply and control panels.

Mechanical treatment equipment can be produced for transportation in following ways:

- for road transportation by truck,

- for transportation inside standard closed sea container 20' DC (20'x8'x8,6'') or 40' HC (40'x8'x9,6'').